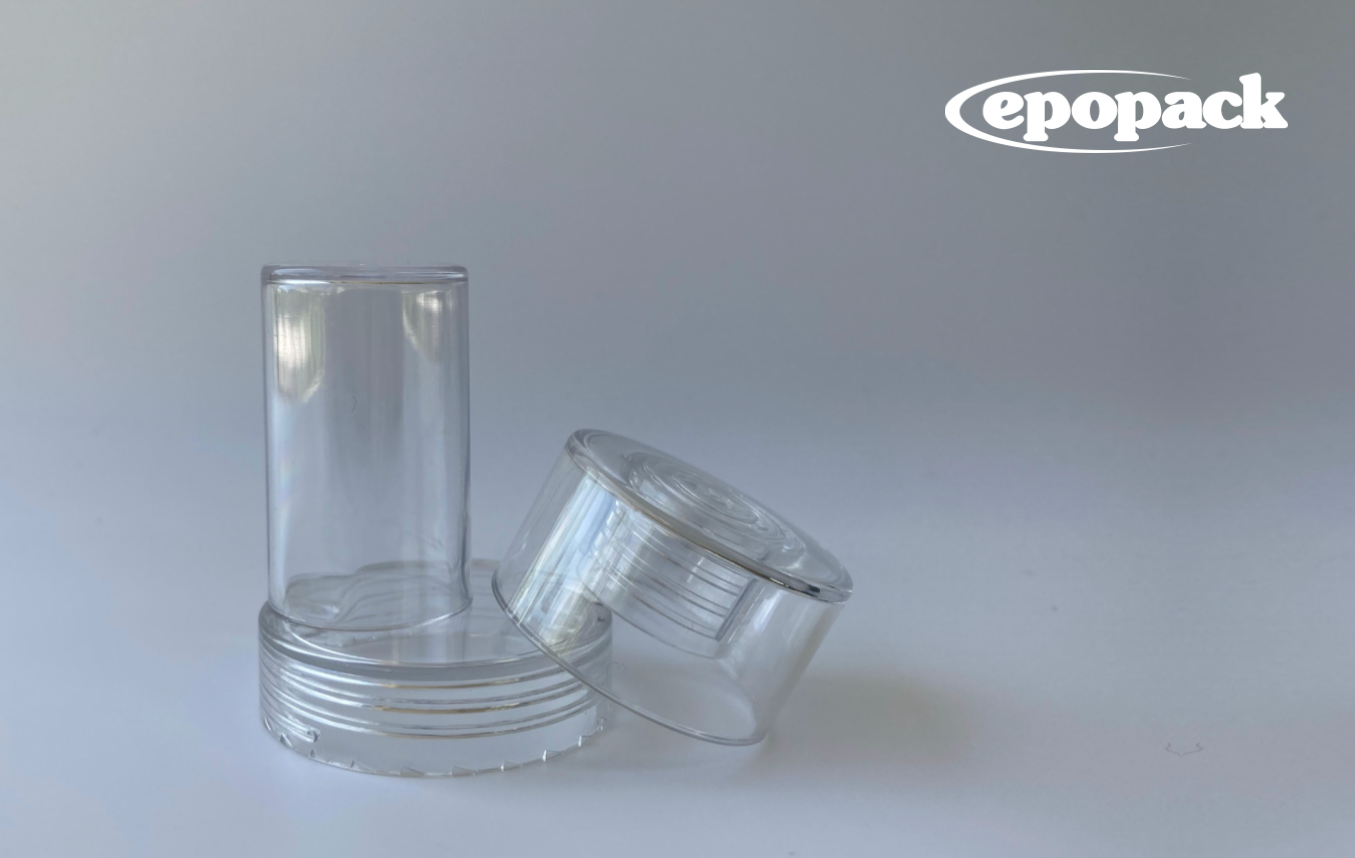

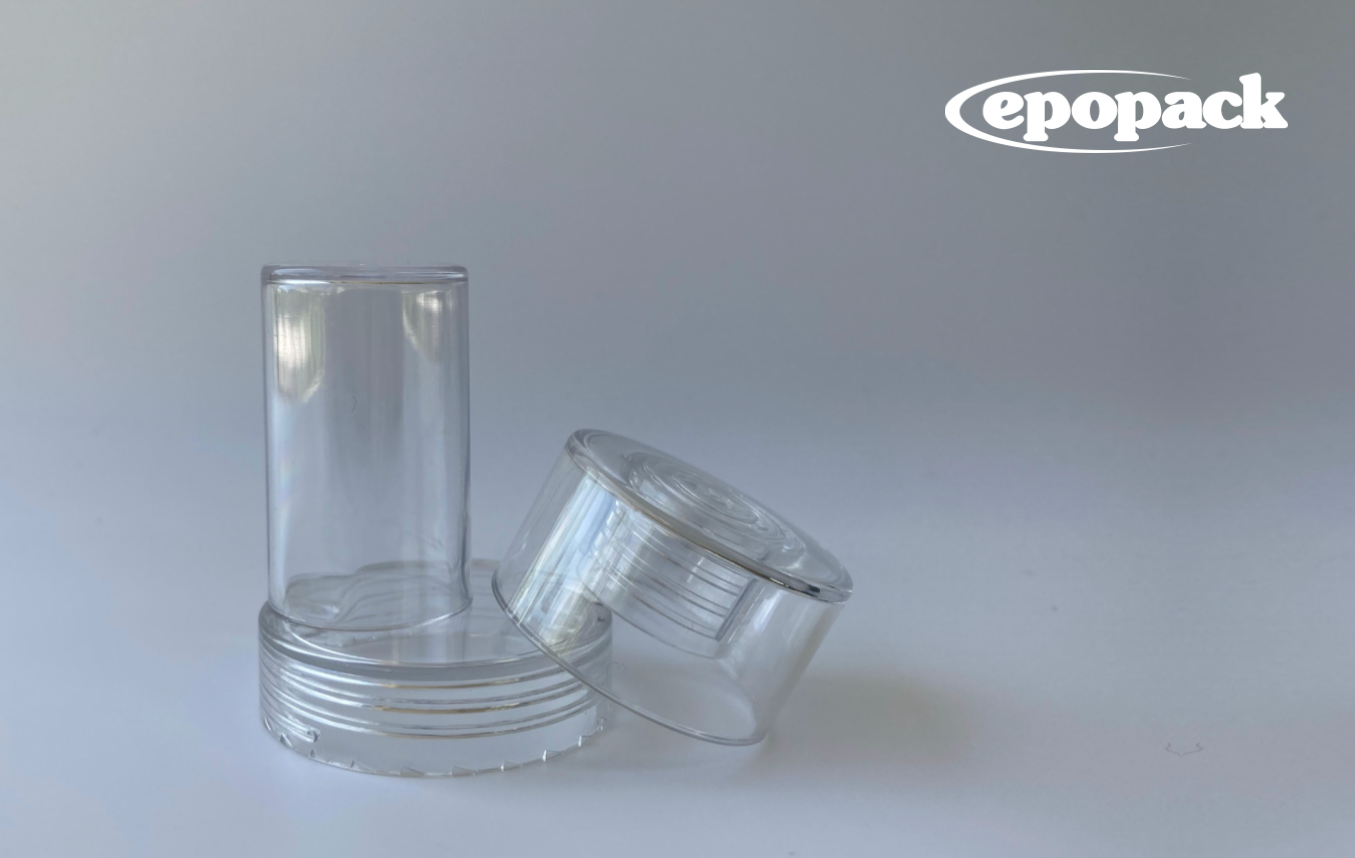

PET Caps: The simple solution to combat the cracking issue

Plastic caps have always been a key part of packaging solutions but their true importance has often been overlooked. Caps are important barriers to prevent any leakage, help to provide a clean design silhouette and will be a major part of the user experience, but not all caps are made the same.

Common cap materials can be brittle, reactive to temperature changes, less adaptable for design and unfortunately break. One common issue seen by consumers and manufacturers alike are cracking caps. Cracking can cause many different issues that interfere with the products integrity and lead to disposal of broken packaging, all equaling a negative experience.

PET may be the answer to this long term problem as this material has a host of advantages compared to conventional plastics commonly used in cap manufacturing. PET is the ideal material because of its durability, resistance, and added recyclability benefit.

PET Caps: The simple solution to combat the cracking issue

Durability: PET is a flexible and strong material option that can withstand high stress and temperature fluctuations. Its technical properties provide a balance between rigidity and flexibility making it an excellent option that excels in a variety of conditions

Resistance: PET has great strength, heat resistance and a high resistance to chemicals, impact and moisture which makes it an ideal option for a wide variety of formulations

BONUS Recyclability: PET has international recycling code #1, making it the most widely recycled plastic in the world. PET used as a replacement for conventional plastic caps can help make recycling easier

PET material caps may be the simple solution to the cracking-problem. As highlighted above there are many advantages that PET carries that make it an effective and thoughtful material choice. It can help reduce potential risks and failures, all the while being a beautiful and sustainable option. At EPOPACK we will help combat these common problems and help find a solution.

Facing any packaging issues? Contact us to see how we can help. Email:

amy@epopack.com